Crushers are vital machines in many industries such as mining, construction, and recycling; they help in reducing large stones and materials into smaller sizes that can be managed with ease. Nonetheless, constant wearing out of crushers causes breakdowns and lower efficiencies. That is where crusher spare parts come into play. This article will look at the importance of these spare parts and how they contribute to the smooth running and optimal functioning of crushers.

Significance of Crusher Spare Parts

Better Crusher Performance

Crusher spare parts are very important for the effective operation of crushers. When some parts are worn or damaged it affects machine efficiency and output greatly.

Reduced Downtime

Downtime due to equipment breakdowns can be expensive for any business. Companies can minimize downtime by having crusher spare parts on hand enabling them to continue their operations without interruption.

Cost Reductions

There are significant savings that can be realized by investing in good-quality crusher spare parts over time. Businesses can avoid complete machine replacements which would cost a lot more money by simply replacing the necessary components only.

Divisions in Crusher Spare Parts

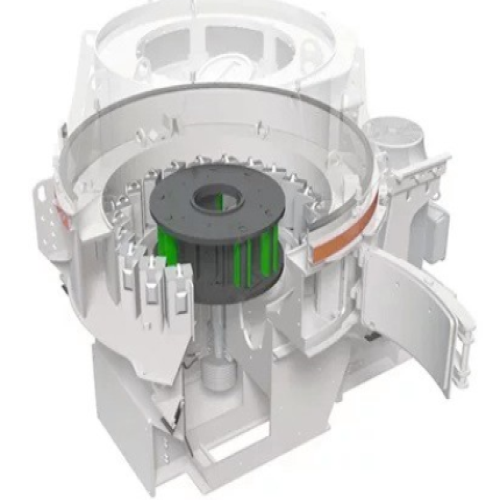

Crusher Wear Parts

The crusher wear parts are designed to resist the materials’ wearing properties. These comprise jaw plates, concaves, and mantles. They undergo extreme stress and frequent wearing out, hence their regular replacement is critical for maintaining crushers’ efficiency and productivity.

Crusher Mechanical Part

Apart from worn-out components, crushers also need various mechanical sections for smooth working. Such as bearings, seals, gears, and belts. Regular check-ups and replacement of these mechanical parts can avoid a major breakdown and boost a crusher’s lifespan.

Choosing the Right Crusher Spare Parts

It is essential to choose the right crusher spare parts if you want to achieve optimum performance and durability. Some of the things to consider include; the type of crusher, application requirements as well and quality and dependability of the supplier. Working with reputable manufacturers and suppliers guarantees the availability of genuine replacements that match every model of crusher. Here are the Best 5 Crusher Spare Parts Suppliers.

1, Matec Solutions

Website: https://www.matecmining.com/

Matec Solutions, headquartered in Beijing, China, is a dynamic joint venture group with 20 years of expertise as a premier supplier of wear-resistant products. Our unwavering commitment lies in pioneering the technological advancement of wear-resistant materials for the mining and aggregates sector. With a global footprint spanning 60 countries, we have earned acclaim for delivering dependable and tailored spare parts. Our comprehensive range of offerings caters to various equipment such as crushers, slurry pumps, mills, vibrating screens, hydrocyclones, and flotation systems. Through relentless innovation, we have evolved into a holistic wear-resistant solution provider for the mining industry. At Matec Solutions, we seamlessly integrate cutting-edge technology with industry-leading expertise to ensure optimal performance and longevity, empowering our clients to thrive in the most demanding operational environments.

2, HMA

Website: https://hmagrp.com/

HMA Wear Solutions presents an extensive array of Processing Equipment designed to cater to the demands of contemporary mineral processing requirements. The dedicated team at HMA prides itself on extending unwavering support to end users, striving to deliver solutions, service, sales, and technical assistance for both principle-supplied equipment and HMA-manufactured products.

At HMA, the focus revolves around collaborating closely with valued clients, aiming to streamline plant operations by reducing operating costs while optimizing process efficiency.

The equipment range encompasses GTech Cyclones (Dense Medium & Classification), Eriez Magnetics, Eriez Flotation, and Conn-Weld Screens. Leveraging technical support from trusted partners, coupled with their expertise and the flexibility of both local and global manufacturing options, HMA ensures they can effectively address the diverse needs of their customers.

Conn-Weld® Circular Motion (Incline) Vibrating Screens

Conn-Weld® Banana Style Vibrating Screens

3, CMS Cepcor®

Website: https://www.cmscepcor.com/

CMS Cepcor®, recognized as Europe’s premier aftermarket manufacturer and supplier, specializes in providing crusher spare parts, mining-grade crusher liners, and comprehensive crusher service to the mining sector. Additionally, they hold the distinction of being Europe’s largest aftermarket manufacturer and supplier of high-quality crusher spare parts for screens and asphalt plants, catering to a global clientele spanning the mining, quarrying, demolition, and recycling industries. Their esteemed status as leaders in Europe is attributed to the extensive range of products and services they offer, supported by multiple accreditations from top industry bodies.

Jaw Crusher parts

Crusher Spare Parts

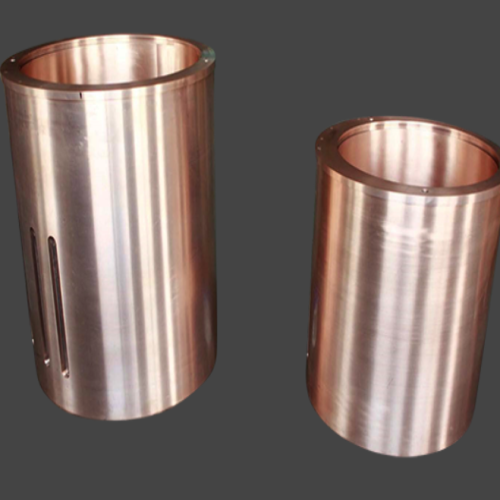

4, Zhili Wear parts

Website: https://www.zhiliwearparts.com/

Established in 1992, Luoyang Zhili New Materials stands as a premier global hub for wear-resistant materials processing. They specialize in delivering top-notch wearing parts services to industries such as mining, cement, power plants, steel, and coal.

The company boasts an exceptional team of technical experts, comprising 8 engineers, including 2 senior engineers, 3 engineers, and 3 assistant engineers. Moreover, they take pride in their talented workforce, which includes 6 postgraduates, 15 undergraduates, and 10 junior college students, all possessing a blend of skill and integrity.

Equipped with state-of-the-art production facilities, Luoyang Zhili New Materials ensures efficiency and quality in their operations. Their equipment includes middle-frequency furnaces, featuring 2 sets of 2-ton furnaces and 3 sets of 1.5-ton furnaces. Additionally, they employ water glass sand casting and a comprehensive set of lost foam casting equipment. With a full suite of machining equipment, the company ensures they meets the highest standards in product processing capabilities.

Jaw crusher spare parts

Stone Crusher Hammer

5, Crusher part International

Website: https://crusherpartsinternational.com/

CPI stands as the Genuine Alternative to OEM Parts, offering aftermarket replacement Spare and Wear Parts of the highest quality globally. Crusher Parts International caters to Mines, Quarries, and Independent Contractors across the world, ensuring uninterrupted plant operations with minimal downtime.

Their mission revolves around supporting the global mining industry by delivering cost-effective solutions without compromising on quality and safety standards.

Jaw crusher

Crusher Spare parts